-

How to install a 3.5L 6G74 engine into a Twin Turbo Stealth or 3000GT:

- Heigher deck height means it can be stroked to over 4.1L

- More cubic inches means more low end torque

- More cubic inches means that less boost is required to get same power level as 6G72, more power on pump gas!

- If you try to you can make the engine look stock to anyone but a expert on 3000GT and Stealths.

- a 4.0L twin turbo engine is basically a 2.0L engine for each turbo. There are a huge amount of DSM turbo optimized

for a 2.0L engine. More options are always good. - Engine swaps are not emissions legal, although it would be easy to hide to most people

- Bigger stoke means higher pistons accelleration which could limit RPMS

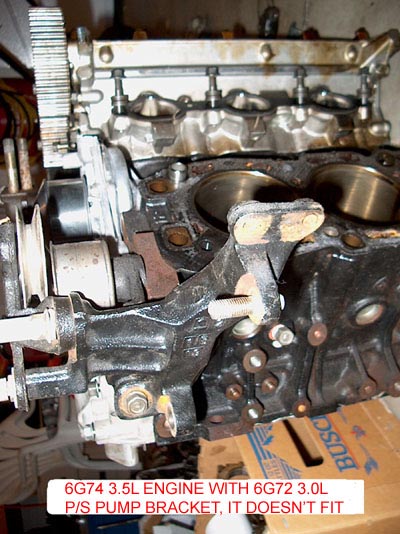

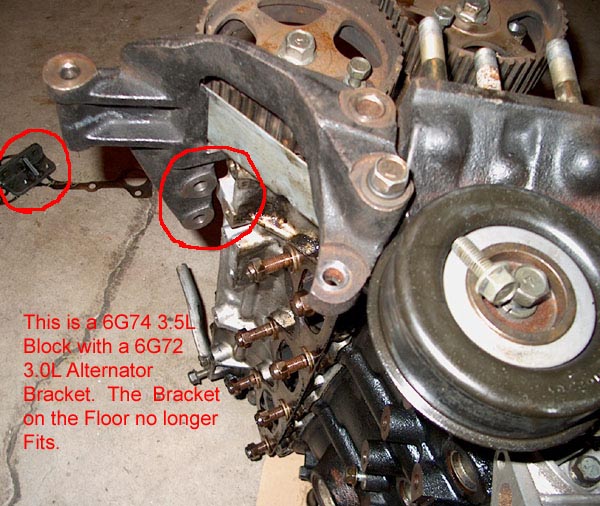

- Wider engine means many accessories don't fit w/o modification, like alternator and P/S pump.

- Higher engine means there is no room for strut tower bar, and engine may hit some hoods

- Heavier engine and more weight on front will mess up the cars cornering balance

- With stock pistons higher compressions raio (10:1 vs. 8:1) means that lower boost will be needed to prevent detonation

- 6G74 Block does not have oil squiters to cool pistons so lower boost may be needed to prevent detonation

- Avoid SOHC Diamante and Montero motors, they need a LOT of modifications to work

- 94-96 DOHC 3.5L Montero motors are a decent choice but they have cast cranks and accesories still need a lot of Modifications

The dipstick tube will be on the back of the engine too.

The Montero Oilpan hits a 3S frame and requires major modifications in addition to modifications to clear transfer case

See my Parts Comparison Pictures page for pictures of Montero DOHC engine.

- The BEST engine is a JSPEC 6G74 engine from a Front wheel drive Mitsubishi Debonaire, Pajaro, or Kia Grandure (mitsubishi made engine)

I would suggest that a JSPEC FWD 6G74 engine is the ONLY engine to consider, This web page is dedicated to this engine.

The Engine I recieved had a forged crank in it! That alone makes this the only engine worth considering!

- It is critical that you buy an engine with all of the accessories since the critical parts are not available in America.

See the next section for a list of parts that MUST come with the engine for this swap to be sucessful!

- Lower intake manifold on 6G74 is wider than a 6G72, Note 6g72 Upper intake manifold will bolt to 6G74 lower intake plenum

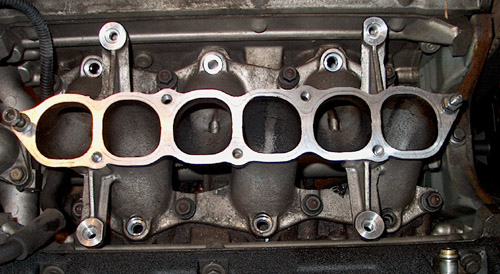

Below is 6G74 3.5L block with correct lower intake manifold

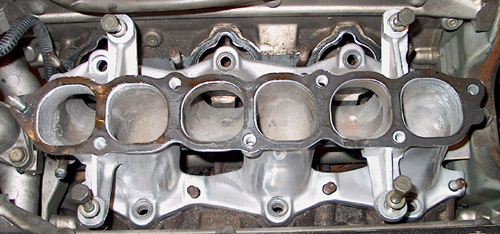

Below is 6G74 3.5L block with smaller 3.0L 6G72 lower intake manifold

You can see that the 6g72 Lower plenum doesn't fit at all.

- Lower Timing belt cover

- Upper timing belt covers

- Water Valley crossover tube that goes from drivers to passenger side of engine

They are different because the tube support bolts to the head, which is in a different location.

The tubes are so close in shape that I am sure a 6G72 part could be made to work with a litte effort.

- CAM gears on 6G74 engine have timing mark 1/2tooth off, You can modify 6G72 gears but the 6G74 gears are easier

See my parts comparison page to see difference between gears. - Water Housing that goes from front to rear head on passenger side of engine

The 6G74 heads are farther apart so that the 6G72TT 3.0L water housing does not fit .

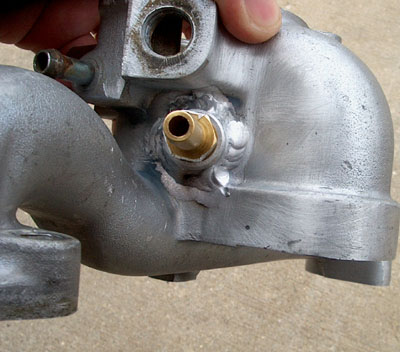

The 6G74 water housing bolts up but if you have a turbo car it must be modified to add the turbo water supply and return fittings.

- 6G72 Power steering pump bracket AND power steering belt tensioner pulley, The 6G72 parts just don't fit.

- 6G72 Alternator Mounting bracket: The best way to do this swap is to use the 6G74 Bracket

I figured out that the 6g72 bracket can be used but only if is cut down and an adpater bracket made.

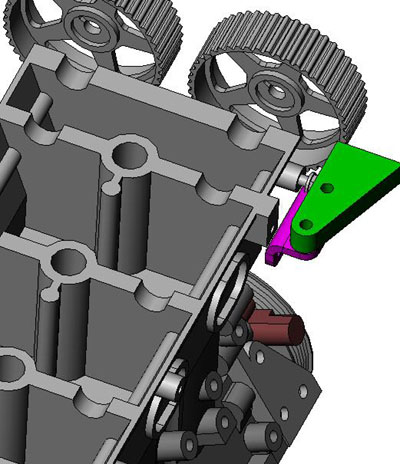

This is a computer model I made of 6G74 engine. I only modeled part of the altenator bracket (thats green).

This first picture shows the stock adapter bracket location (thats purple) for a 6G72 engine.

If you look closely you can see the Green alternator bracket blocks the moungting holes in the 6G74 head location

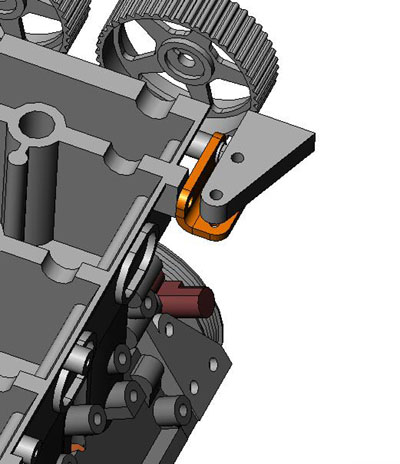

This second picture shows the new bracket I designed in orange. The green bracket is just far enough from the heads

for room for a mounting bolt. The new bracket mounts extra low and what is not shown is some flat spacers I will use

between the alternator bracket and my new bracket, SIMPLE!

- Crank shaft pully is physically the same size but the center weight is a little different, us the 6G74 pulley if possible

- The 6G72 TT Radiator fill tube on top of thermostat housing. has a water fitting on it that is needed for turbo engine

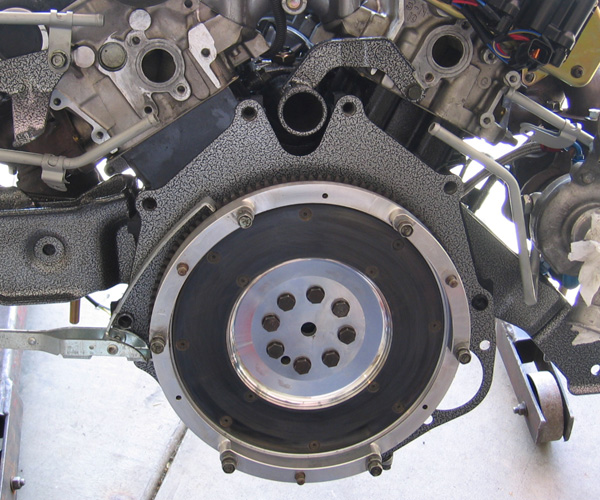

- The plate that goes between the engine and transmission needs to be re-used from 6G72 engine after being trimmed slightly.

- Oil filter mounting bracket from 6G72TT engine is needed if an oil cooler is used, all TT engines use oil cooler.

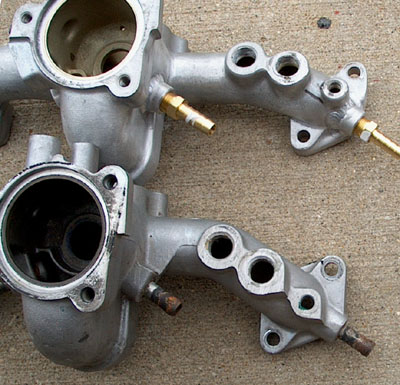

The Stock 6G74 Engine oil filter bracket shown below, it is identical to part used on a 6G72 NA engine.

The 6G72TT 3L oil filter bracket bolts right to the 6G74 3.5L block

- Flywheel from 6G72 engine needs to be re-used

- Throttle Body from 6G72 engine needs to be re-used.

- For NA engine either the 6G74 or 6G72 upper intake manifolf will work.

With a turbo car the 6G72 TT upper intake manifold is needed. - 6G72 Engine mouting brackets have to be re-used

- A 6G72 93+ oil pump is a direct fit!

- A 6G72 93+ Water pump is a direct fit!

- A 6G72 Radiator Fill neck is needed, Note The Turbo housing has a extra water fitting for turbo coolant line.

- 6G74 Water crossover tube must be tapped for coolant lines to go to turbos. I had 3 aluminum pipe thread bungs welded on.

The 4th water fitting is in the 6G72TT radiator cap housing.

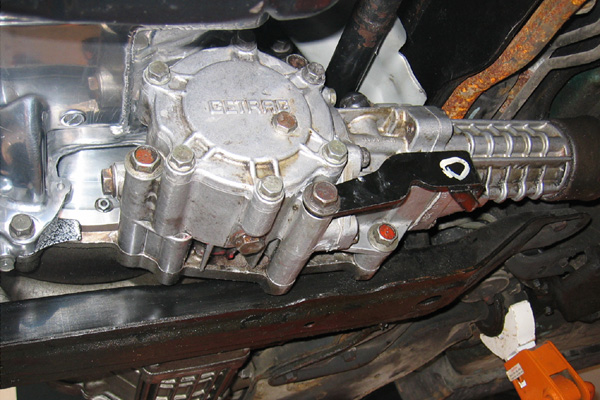

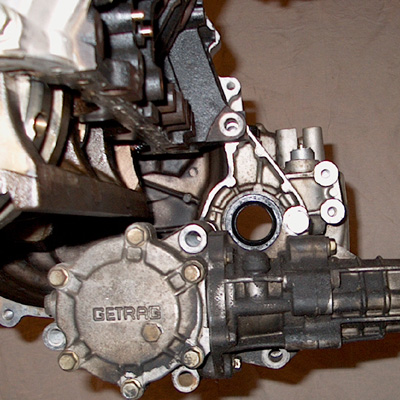

- 6G74 Oil pan requires major modifications to make clearance for AWD transfercase.

The best way to do this is to bolt a transmission to the engine and cut the oil pan until the

transfercase can be installed and removed from the transmission. The transfer case needs

about 2-3" to slide off the output shaft. It is very important that you find out how much clearance

you need and add another inch to make 100% sure you can remove the transfercase with the transmission

bolted to the engine.

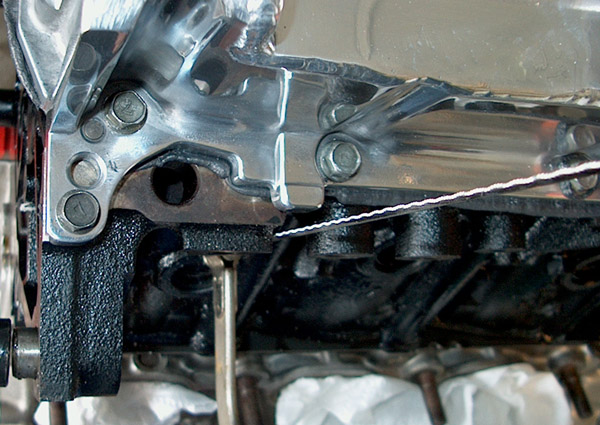

This image shows the oil pan with a notch that is NOT big enough to remove the transfercase.

I have to remove the cover from the transfercase to remove the transfercase. DON'T repeat my mistake!

Some pictures during the oilpan modification process.

- The main bearing cradle will need to be ground down slightly to make room for the transfer case bulge in the oil pan

- The 6G74 Grankshaft doesn't have the pin in it to align to the flywheel, I ran without it but it should probably be added

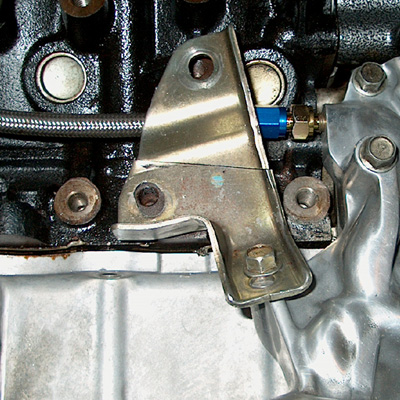

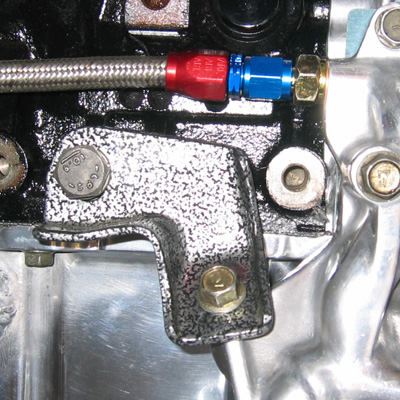

- The oil filter housing support bracket had to be cut down and re-drilled to fit correctly

I welded the old holes shut and powdercoated it. It came out great!

- 6G74 is set up for 4-bolt main style Crank angle and Cam angle sensors, 91 & 92 cars will need to install a cam driven

sensor or a jumper harness.

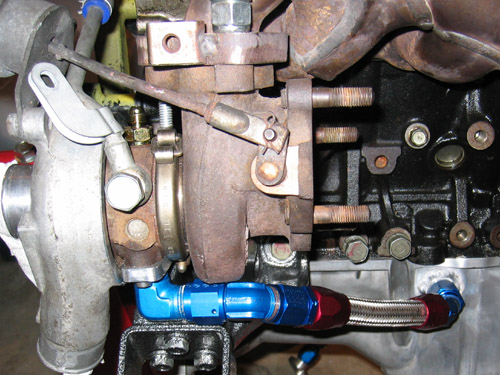

- With a turbo Conversion the 6G72 3.0L Turbo oil supply and retrun lines must be lengthened. They are 20mm too short on 3.5L

I Made custom steel briaded lines, these were VERY expensive and time consuming.

Custom Rear turbo oil return line

Custom Front turbo oil return line

If I had to do this again I would just cut stock oil retun lines and clamp a 4" piece of #12 braided hose to extend to oil returns.

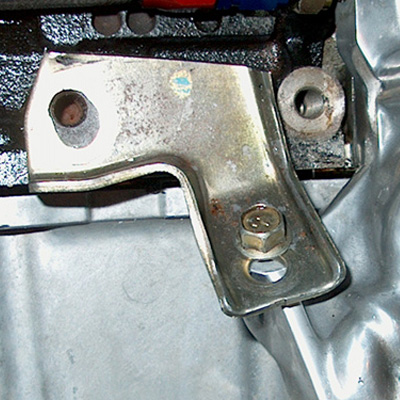

- Many 6G74 blocks must be modified so that the 6G72 rear engine mount will bolt up.

I had to modify the 6G74 main block itself so that the rear engine mount would fit correctly.

I have been told that this modification does not have to be done if you use a 94-96 Montero Block.

Rear of Engine block before cut.

Rear of Engine block partially cut, I had to cut the rest of these 3 bosses off then file it down by hand.

This really should have been done by a machine shop but I took my time and it is working fine.

GTO NEMESIS game me permission to show these great pictures of how he modified his block using a piece of

steel for a straight edge to guide the hand grinder.

- With 10:1 compression ratio and turbos the stock ECU has problems adjusting. I talked to other people who did

this swap and the most common problem is a dangerous lean spike at 3000 RPM. My theory is that the high compression

large displacement engine flows more air at lower RPM than the stock ECU is mapped for, even when a fuel controller

is used. Using an AEM standalone ECU will fix this problem, but I think lowering the compression ratio is a better solution

GTO NEMESIS game me permission to show this picute of his custom forged 8:1 pistons. Notice how deep the dish in the

piston is to lower the compression ratio, pretty cool!

- The stock downpipe will no longer fit. You can either make a custom downpipe or add spacers to the stock down pipe.

- IF you have a 1st gen Turbo engine of a NA engine the A/C belt tensioner bracket will be too long

A special thanks to Jeff Van Ordsdale "Gatecrasher" for sending me this picture a long time ago.

This is a 1st gen bracket that does not fit on 6G74 engine. You have to cut off APPROXIMATELY 1/2"

Warning! I cut mine down TOO FAR far, it worked but my alternater belt always squealed and after 1 year

the alternator belt started shreading. I bought the correct 4-bolt main bracket and discovered I had cut

mine 2 mm too short.

On the left is the bracket I cut down too far, on the right is a 2nd Gen 6G72 tensioner bracket

Last updated 4/18/09

I sold my 92 Stealth Twin Turbo with 3.5L conversion but I still get questions about it all the time

This webpage provides step by step instructions on how to do this conversion

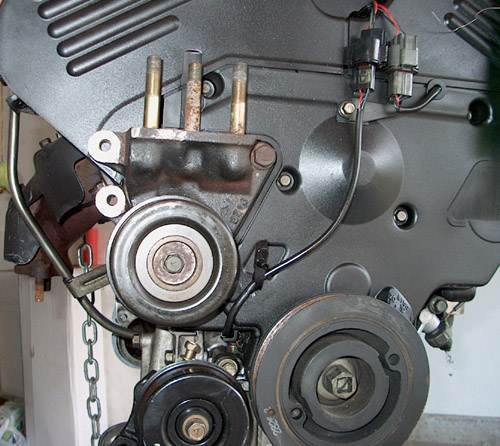

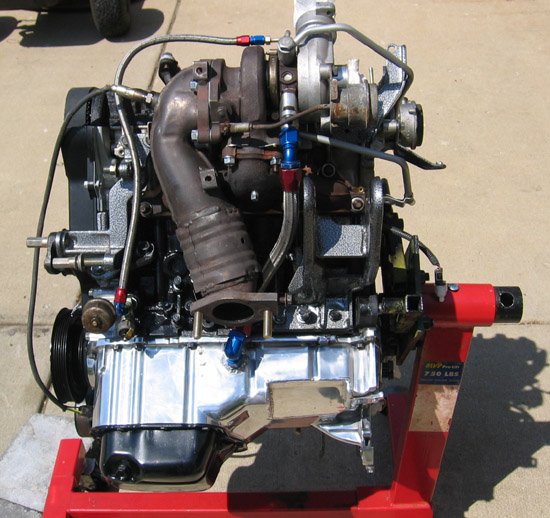

The finished installation looked VERY stock

A closer look at the engine shows that I got a little crazy: polishing the oil pan, braided stainless oil lines and silvervein powdercoating

Why you should consider this conversion:

Now that stroker kits for 6G72 engine are becoming more common this swap is not necessary for 99.99% of of people considering it.

But if you want something different then you can enjoy some of the advantages listed below:

A 6G74 engine theoretically has more potential than the 6G72 engine.

The deck height on the 6G74 engine is 18mm higher than the 6G72 engine so it can be stroked IF you want to have a billet crank made $$$$

More cubic inches means more potetial power on pump gas which will hopefully make this an awesome street engine

The extra displacement will also spool the turbos faster!

For more in depth study of the engine specifications and stroker math! 6G74 Details

For more side by side parts comparisons! 6G74 Part Comparison Pictures

This swap only requires a few parts to be modified see details here! 6G74 Parts Modified

More pictures More 6G74 Pictures!

How Much will it cost?:

This swap can be done for under $3000 if you keep the stock 10:1 compression ratio.

If you are using turbos you really want to lower compression to 8.5/1. 3SX sellls the parts to do this

3SX 6G74 pisons for aprox $800

3SX 6G74 rods for aprox $750

PROs and CONs of swapping to 6G74:

PROS

CONS

STEP 1: Find the correct 6G74 Engine :

You must be VERY carefull selecting the engine. I bought mine from Eric Japan Engines in Chicago (773) 463-8108.

It is critical that you buy an engine with all of the acessories since the critical parts are not available in America.

All of the 6G74 Engines will bolt to the transmission but the accesorries vary a LOT.

6G74 parts you MUST get from JSPEC engine:

Make sure you Jspec engine has the following parts or you are going to have a VERY difficult time getting them:

STEP 2: 6G72 Parts that need to be moved to 6G74 Engine:

The parts that are directly interchangeable, or that must be reused from old 6G72 engine are:

STEP 3: The following Parts MUST be modified:

Home